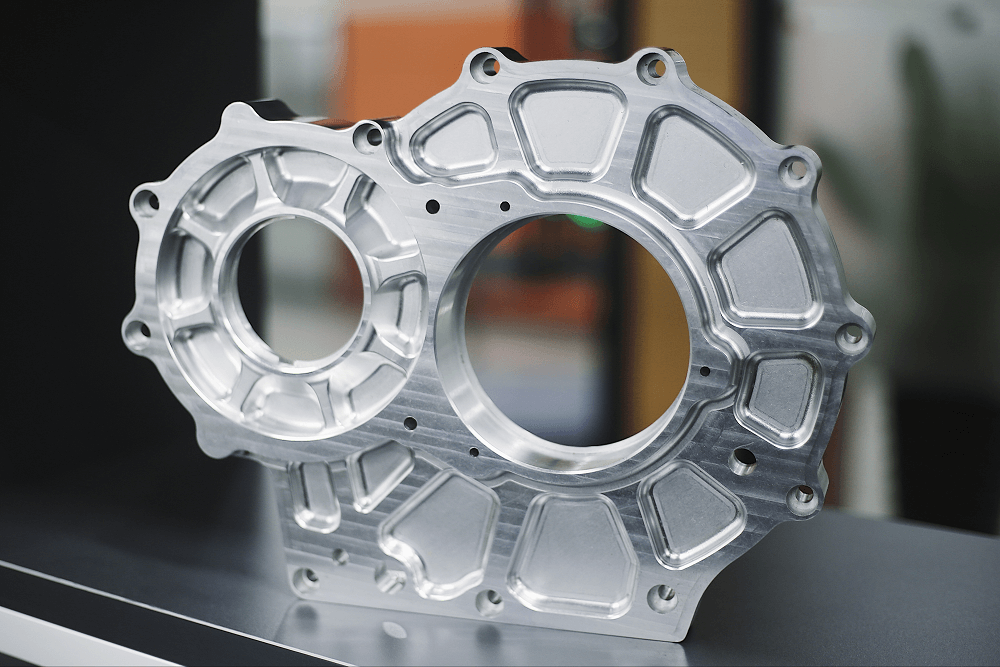

Aluminum

Aluminum is a versatile material with properties that make it ideal for CNC machining. Aluminum has excellent machinability, welding and electroplating properties as well as good corrosion resistance. The metal is also characterized by a high strength-to-weight ratio and good temperature resistance. After machining, aluminum has a low risk of deformation or defects and is easy to polish and color.

Because of these properties, aluminum is a broadly used metal in many industries, including automotive, defense, aerospace, transportation, construction, packaging, electronics, consumer goods and more.

Information of Aluminum

| Features | Info |

| Subtypes | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, etc |

Process | CNC machining, injection molding, sheet metal fabrication |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Light & economic, used from prototyping to production |

Finishing Options | Alodine, Anodizing Types 2, 3, 3 + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

Available Aluminum Subtypes

| Subtypes | Yield Strength | Elongation at Break | Hardness | Density | Maximum Temp |

Aluminum 6061-T6 | 35,000 PSI | 12.50% | Brinell 95 | 2.768 g/㎤ 0.1 lbs / cu. in. | 1080° F |

Aluminum 7075-T6 | 68,000 psi | 11% | Rockwell B86 | 2.768 g/㎤ 0.1 lbs / cu. in | 380° F |

Aluminum 5052 | 23,000 psi | 8% | Brinell 60 | 2.768 g/㎤ 0.1 lbs / cu. in. | 300° F |

Aluminum 6063 | 16,900 psi | 11% | Brinell 55 | 2.768 g/㎤ 0.1 lbs / cu. in. | 212° F |