- BAOAN SHENZHEN , CHINA

- +86 0755 29920613

- Jackluo@szjsd.com.cn

CNC machining services for rapid prototypes and production parts. Get instant CNC quotes today, and order your custom metal and plastic parts.

Our CNC Machining Services

If you need custom machined parts with complex geometries, or get end-use products in the shortest possible time, cncjsd is good enough to break through all of that and achieve your idea immediately. We operate over 150 sets of 3, 4, and 5-axis CNC machines, and offer 100+ different types of materials and surface finishes, guaranteeing quick turnaround and quality of one-off prototypes and production parts.

CNC Milling

CNC milling removes materials from the workpiece to create custom-designed parts with flat surface using cutting tool or multi-point milling cutters.

WIth our 3-axis & 5-axis CNC milling services, you can get milled parts with tight tolerance up to +-0.005mm (+-0.0002 in.)

CNC Turning

CNC turning shears materials from the ouside of a rod at incredible speeds using a spinning tool. At cncjsd, we apply 50+ CNC lathes and CNC turning centers to create round or cylindrical turned parts with extreme precision that consistantly meet customers’ expectations.

From CNC Prototyping to Production

CNC machining is a computerized and versatile manufacturing process ideal for rapid prototyping and on demand production. Here are the custom CNC services available at the cncjsd.

Rapid Prototyping

With our instant quotation platform and strong capacity, you can get excepted prototypes in short lead times. This allows you to quickly test prototype parts and get them to market.

Bridge Production

Bridge-to-production is critical for closing the gap between the part design and the actual product rollout. No worries. Our professional engineering team is always ready to provide practical design suggestions for your low volume machined parts.

On-Demand Production

Our full service for on-demand production orders ensures that you get high precison and high standard of quality products. Enhanced production rate also allows for just-in-time delivery of production parts.

CNC Machining Tolerances and Standards

With precision CNC machining services, cncjsd is your ideal partner to create precision machined prototypes and parts. Our standard CNC machining tolerances for metals is ISO 2768-f and for plastics is ISO 2768-m. We can also achieve special tolerances as long as you indicate your requirements on your drawing.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 4000×1500×600 mm

157.5×59.1×23.6 in. | 200×500 mm

7.9×19.7 in. |

| Minimum Part Size | 4×4 mm

0.1×0.1 in. | 2×2 mm

0.079×0.079 in. |

| Minimum Feature Size | Φ 0.50 mm

Φ 0.00197 in. | Φ 0.50 mm

Φ 0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-f Plastics: ISO 2768-m | Metals: ISO 2768-f Plastics: ISO 2768-m |

| Linear Dimension | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Hole Diameters (Not Reamed) | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Shaft Diameters | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter

Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter

Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| cncjsd can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of 0.5 mm, depth of 0.1 mm cncjsd can use CNC engraving or laser carving to create standard text based on customers’ requirements. | cncjsd can use laser marking to create standard text for CNC turned parts. |

| Lead Time | 5 business days | 5 business days |

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If don’t want as-machined parts, select a surface finishing for your custom parts. At cncjsd, we offer several common surface finishes that help improve functionality and aesthetics.

| Name | Description | Materials | Color | Texture | Link |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | - |

| Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | Matte | - |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | - |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | n/a | Smooth, glossy finish | - |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | n/a | Glossy | - |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | satin | - |

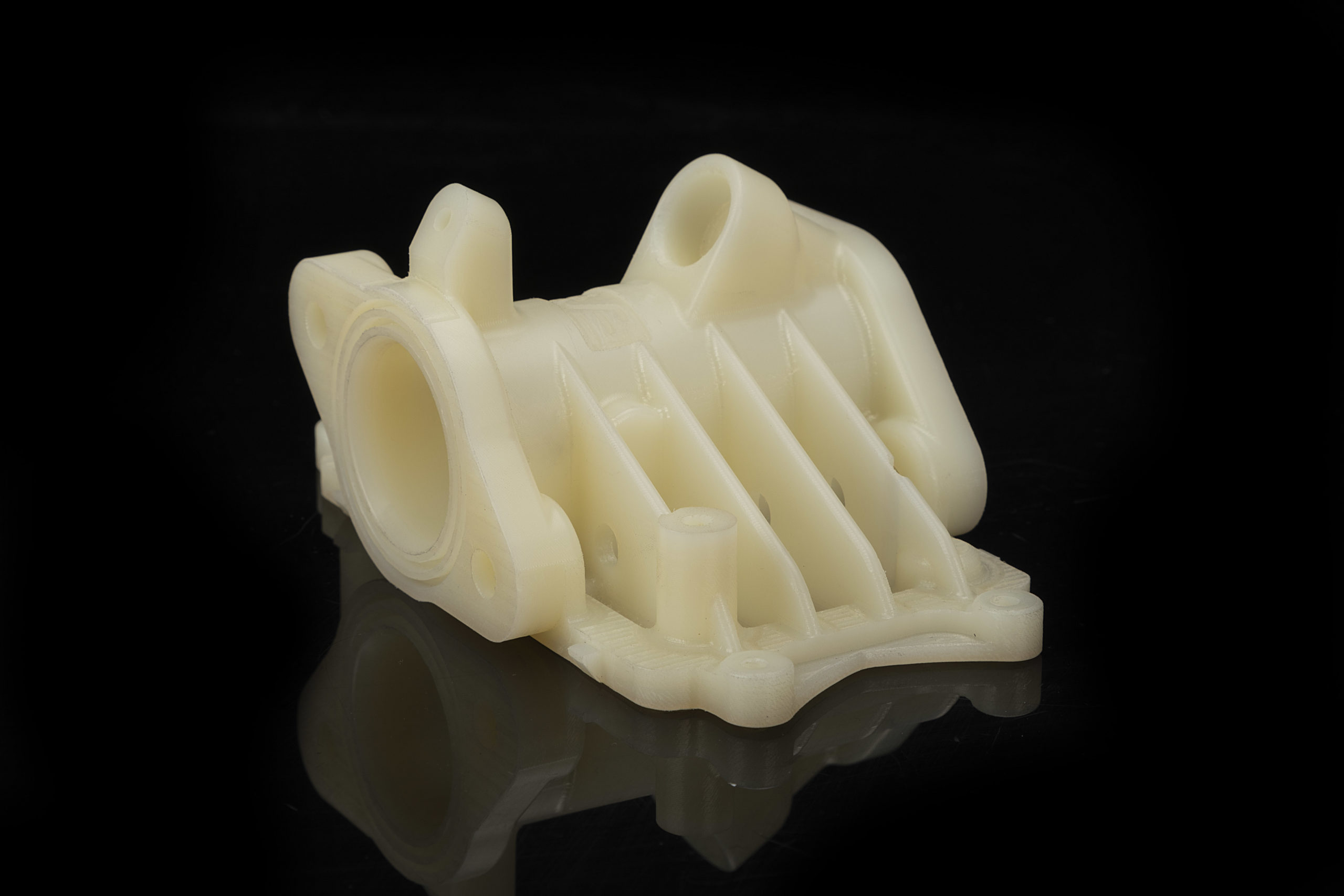

Gallery of CNC Machined Parts

Check out our extensive gallery that shows precision machined prototypes and parts from our valued customers.

Why Choose Our Custom CNC Machining Service

Online Instant Quote & DFM Analysis

No need to write a quote request email, get instant CNC quotes by simply uploading your design files. Our digital quoting platform analyzes your part geometry, and provides real-time & competitive pricing and comprehensive DFM feedback.

Consistent High Quality

We strictly implement a quality management system to ensure consistent, expected quality on the products. Full inspections also make sure you receive precision machined parts devoid of unwanted defects.

Fast Lead Time

Not only do we have a digital CNC machining services platform that provides faster ordering process, we also own domestic workshops and state-of-the-art machinery to accelerate the production of your prototypes or parts.

24/7 Engineering Support

No matter where you are, you can get our 24/7 engeering support all year around. Our experienced engineer can provide you with the most appropriate solution to your part design, material selection, and surface finishing options and even lead time.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Hi, Fiona. I’d like to thank you and everybody at cncjsd for contributing to the great service we received. You constantly handle our difficult CNC machining projects, and offer instant quotation and free DFM analysis for the part design. Best of all, you show superior quality in short lead times. Our department supervisor confirmed that you will continue making these parts now. The quality is outstanding!

Luc Szorc

– Mechanical Engineer

Our small R&D group requires high precision CNC machined parts within short periods. cncjsd consistently delivers these parts at great values and quick turnarounds. The reliability of this company places them above our other part suppliers.

Kayne Espinosa

– Project Manager

We asked cncjsd to fabricate parts for a critical supplier demo, and you came through with a short lead time. Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors. We look forward to doing future projects with you guys.

Hari Mackenzie

– Engineer

From the instant and accurate quotation to production process to the timely delivery of parts, cncjsd responded to our demands with complete professionalism. They handled every aspect of this CNC machining project quickly and cost-effectively. We will surely work with them again in the future.

Mark Alford

– Chief Engineer

cncjsd has been our quality supplier of CNC machined parts. Fast delivery is very important for our business, and cncjsd always offers short lead time and competitive pricing. Andy responds fast to all our emails and questions. This has improved our working relationship, and we continue to value this partnership.

Piscary Herskovic

– Product Designer

Hi, Fiona. I’d like to thank you and everybody at cncjsd for contributing to the great service we received. You constantly handle our difficult CNC machining projects, and offer instant quotation and free DFM analysis for the part design. Best of all, you show superior quality in short lead times. Our department supervisor confirmed that you will continue making these parts now. The quality is outstanding!

Luc Szorc

– Mechanical Engineer

Our small R&D group requires high precision CNC machined parts within short periods. cncjsd consistently delivers these parts at great values and quick turnarounds. The reliability of this company places them above our other part suppliers.

Kayne Espinosa

– Project Manager

We asked cncjsd to fabricate parts for a critical supplier demo, and you came through with a short lead time. Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors. We look forward to doing future projects with you guys.

Hari Mackenzie

– Engineer

From the instant and accurate quotation to production process to the timely delivery of parts, cncjsd responded to our demands with complete professionalism. They handled every aspect of this CNC machining project quickly and cost-effectively. We will surely work with them again in the future.

Mark Alford

– Chief Engineer

cncjsd has been our quality supplier of CNC machined parts. Fast delivery is very important for our business, and cncjsd always offers short lead time and competitive pricing. Andy responds fast to all our emails and questions. This has improved our working relationship, and we continue to value this partnership.

Piscary Herskovic

– Product Designer

Hi, Fiona. I’d like to thank you and everybody at cncjsd for contributing to the great service we received. You constantly handle our difficult CNC machining projects, and offer instant quotation and free DFM analysis for the part design. Best of all, you show superior quality in short lead times. Our department supervisor confirmed that you will continue making these parts now. The quality is outstanding!

Luc Szorc

– Mechanical Engineer

Our CNC Machining for Various Industrial Applications

cncjsd works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom CNC machining services helps more and more manufacturers bring their idea to products.

Materials for Custom CNC Machining Parts

A numebr of materials can be used in CNC machines, giving you various of options to complete rapid prototyping to production runs of custom complex parts. For your manufacturing needs, we provide instant quotatios of 100+ metals and plastics, and even you can compare prices for different machining materials.

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

356

+

Saticfied Clients

784

+

Project Complate

963

+

Support Team

Request a Quote

Quality Parts Made Easier, Faster