- BAOAN SHENZHEN , CHINA

- +86 0755 29920613

- Jackluo@szjsd.com.cn

Custom engineering and manufacturing services from prototypes to on demand production of sheet metal parts. Low-cost sheet metal fabrication solution for you.

Our Custom Sheet Metal Fabrication Services

Sheet metal fabrication is the most cost-effective choice for custom sheet metal parts and prototypes with uniform wall thickness. cncjsd provides various sheet metal capabilities, from high-quality cutting, punching, and bending, to welding services.

Laser Cutting

Intense lasers cut through 0.5mm to 20mm thick sheet metals to create high-grade prototype sheets for various parts.

Plasma Cutting

CNC plasma cutting is widely used in custom sheet metal services, it is especially suitable for custom cutting of thicker sheet metals.

Bending

Sheet metal bending is used to shape steel, stainless steel, aluminum parts and custom sheet metal prototypes after the cutting process.

Sheet Metal Fabrication From Prototyping to Production

cncjsd custom sheet metal fabrication services can be used for various applications such as mold tooling, rapid prototyping, and custom manufacturing, and more.

Functional Prototype

Custom metal fabrication can be formed into 2D shaped profiles from various metals, creating functional molds for specific parts.

Rapid Prototyping

cncjsd can produce sheet metal prototyping from sheet metal within a short time and at a low cost.

On-Demand Production

From rich selections of materials to sheet metal parts manufacturing and assemblies, to flexible delivery, we provide end-to-end high-volume production solutions.

Sheet Metal Fabrication Standards

To ensure part manufacturability and precision of fabricated prototypes and parts, our custom sheet metal fabrication services are in compliance with the ISO 2768-m.

| Dimension Detail | Metric Units | Imperial Units |

Edge to edge, single surface | +/- 0.127 mm | +/- 0.005 in. |

Edge to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

Hole to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

Bend to edge / hole, single surface | +/- 0.254 mm | +/- 0.010 in. |

Edge to feature, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

Over formed part, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

Bend angle | +/- 1° | |

By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify them in your drawing.

Available Sheet Metal Fabrication Processes

Check out the specific advantages of each sheet metal manufacturing process and choose one for your custom part needs.

| Processes | Description | Thickness | Cutting Area |

| Laser Cutting | Laser cutting is a thermal cutting process that uses high-power laser to cut metals. | Up to 50 mm | Up to 4000 x 6000 mm |

| Plasma Cutting | CNC plasma cutting is suitable for cutting thicker sheet metals. | Up to 50 mm | Up to 4000 x 6000 mm |

| Waterjet Cutting | It is especially useful for cutting very thick metals, including steel. | Up to 300 mm | Up to 3000 x 6000 mm |

| Bending | It’s used to shape custom sheet metal prototypes after the cutting process. | Up to 20 mm | Up to 4000 mm |

Finishing Options for Sheet Metal Fabrication

Choose from a wide variety of finishing options that alter the surface of sheet metal fabricated parts and products to improve their corrosion resistance, enhance cosmetic appearance, and decrease cleaning time.

| Name | Description | Materials | Color | Texture | Link |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | - |

| Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | Matte | - |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | - |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | n/a | Smooth, glossy finish | - |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | n/a | Glossy | - |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | satin | - |

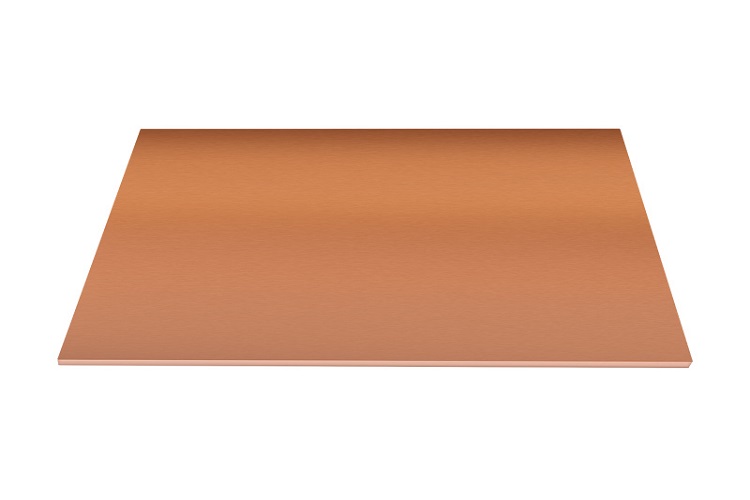

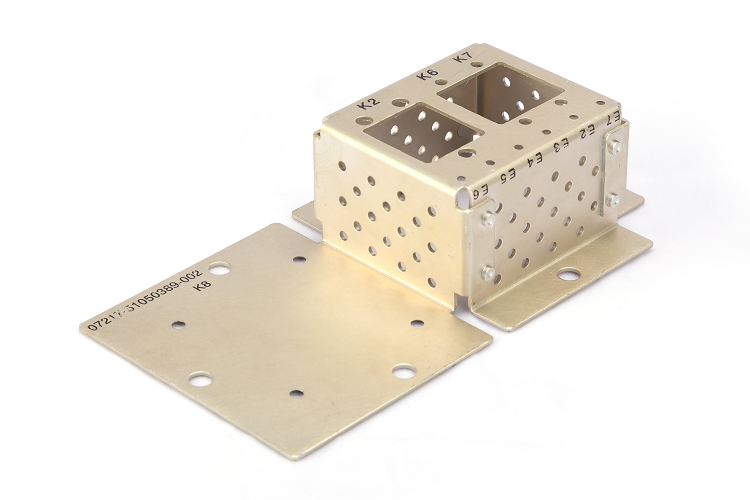

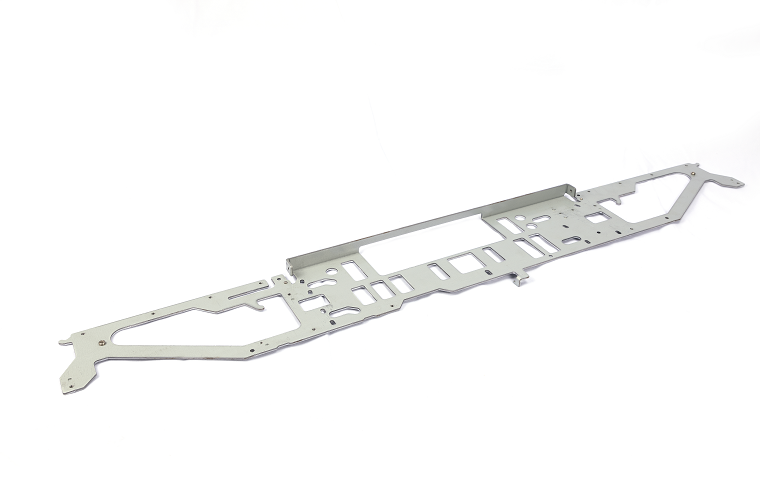

Gallery of Sheet Metal Fabrication Parts

For several years, we have been manufacturing various of metal fabricated parts, prototypes, and various products for different clients. Below are the previous sheet metal fabrication parts we had made.

Why Choose Us for Sheet Metal Fabrication

Fast Online Quotation

Just upload your design files and configure material, finishing options and lead time. Quick quotes for your sheet metal components can be created in just a few clicks.

Assured High Quality

With an ISO 9001:2015 certificated sheet metal manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from cncjsd will exceed your expectations.

Strong Manufacturing Capacity

Our domestic factories in China provide a complete sheet metal project solution through flexible material, surface finish options and infinite manufacturing capacity for low volume and high volume production runs.

Sheet Metal Engineering Support

We provide 24/7 online engineering customer support for your custom sheet metal engineering and manufacturing problems. This includes case-by-case suggestions to help you reduce costs early on in the design phase.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

cncjsd has been a creative and trustworthy partner for both unique ideas and quality parts production for many years. We heartily endorse cncjsd as a one-stop shop for both straightforward and intricate designs. They offer services for design enhancement, large selection of materials and finishing services, and quick responses.

Kleng Ellwood

– Product Engineer

cncjsd is an essential part of our supply chain. They regularly deliver on schedule sheet metal parts and with top-notch quality. They are easy to work with and considerate of their client’s demands. Whether it is repeat orders for parts or one of our numerous last-minute orders, they always deliver.

Feri Russell

– Director of Product Development

I am happy to say that cncjsd is one of our top sources for fabricated metal parts. We have a 4-year relationship with them, and it all began with excellent customer service. They do a fantastic job of informing us about our order progress. We view cncjsd more as a project partner than just a supplier for us in many ways.

Rahim Smyth

– Designer

Hi, Andy. I want to express my gratitude to you and your team for all your efforts in completing the project. Working with cncjsd on this metal fabrication project has been a great pleasure. I wish you a wonderful rest of your summer, and I am confident we will work together again in the future.

Stephen Phearsdorf

– Lead Mechanical

I would like to thank you for working with us on this successful project. Our project team has been very impressed with cncjsd quality of work and timely deliveries. We will definitely keep you in mind for future sheet metal projects and recommend you to other companies.

Derek Armstrong

– Project Manager

cncjsd has been a creative and trustworthy partner for both unique ideas and quality parts production for many years. We heartily endorse cncjsd as a one-stop shop for both straightforward and intricate designs. They offer services for design enhancement, large selection of materials and finishing services, and quick responses.

Kleng Ellwood

– Product Engineer

cncjsd is an essential part of our supply chain. They regularly deliver on schedule sheet metal parts and with top-notch quality. They are easy to work with and considerate of their client’s demands. Whether it is repeat orders for parts or one of our numerous last-minute orders, they always deliver.

Feri Russell

– Director of Product Development

I am happy to say that cncjsd is one of our top sources for fabricated metal parts. We have a 4-year relationship with them, and it all began with excellent customer service. They do a fantastic job of informing us about our order progress. We view cncjsd more as a project partner than just a supplier for us in many ways.

Rahim Smyth

– Designer

Hi, Andy. I want to express my gratitude to you and your team for all your efforts in completing the project. Working with cncjsd on this metal fabrication project has been a great pleasure. I wish you a wonderful rest of your summer, and I am confident we will work together again in the future.

Stephen Phearsdorf

– Lead Mechanical

I would like to thank you for working with us on this successful project. Our project team has been very impressed with cncjsd quality of work and timely deliveries. We will definitely keep you in mind for future sheet metal projects and recommend you to other companies.

Derek Armstrong

– Project Manager

cncjsd has been a creative and trustworthy partner for both unique ideas and quality parts production for many years. We heartily endorse cncjsd as a one-stop shop for both straightforward and intricate designs. They offer services for design enhancement, large selection of materials and finishing services, and quick responses.

Kleng Ellwood

– Product Engineer

Our Injection Molding for Various Industrial Applications

cncjsd works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom injection molding services helps more and more manufacturers bring their idea to products.

Sheet Metal Fabrication Materials

No matter the application and requirement of your sheet metal parts, you’ll find the right material when you trust cncjsd. The following outlines some popular materials available for custom metal fabrication.

Aluminum

Commercially, aluminum is the most sought-after material for sheet metal manufacturing. Its popularity is due to its adaptive qualities and its high thermal conductivity and low resistance rates. Compared to steel—another common sheet metal material—aluminum is more cost-effective and has a higher rate of production. The material also generates the least amount of waste and can easily be reused.

Subtypes: 6061, 5052

Copper

Copper is a broadly used sheet metal fabrication material in many industries as it offers good malleability and ductility. Copper is also well suited for sheet metal fabrication because of its excellent heat conduction properties and electrical conductivity.

Subtypes: 101, C110

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Subtypes: C27400, C28000

Steel

Steel offers a number of beneficial properties for industrial applications, including rigidity, longevity, heat resistance and corrosion resistance. Steel sheet metal is ideal for producing complex designs and parts that require extreme precision. Steel is also cost-efficient to work with and has excellent polishing properties.

Subtypes: SPCC, 1018

Stainless Steel

Stainless steel is the low carbon steel that contains a minimum of 10% chromium by weight. The material properties associated with stainless steel have made it a popular metal within a broad range of industries, including construction, automotive, aerospace and more. Within these industries, Stainless steel is versatile and is an effective choice for many applications.

Subtypes: 301, 304, 316

356

+

Saticfied Clients

784

+

Project Complate

963

+

Support Team

Request a Quote

Quality Parts Made Easier, Faster